Tesla Deep Dive - Learning the Secrets of the Country's most Innovative Upstart Auto

By Martha Hindes

Senior Editor

Michigan Bureau

The Auto Channel

Ask some unenthusiastic observers and they might tell you a common joke about all those bundles of “double A batteries” tied together to provide electricity to propel the electric super car down the road. Ask enthusiasts and it might be the innovative technology that makes it essentially a supercomputer with four wheels attached.

Ask Sandy Munro and he might tell you the only way to find out is to pretend you are a five-year-old with a new toy and immediately take it apart to see what's inside.

Munro has a long history of automotive engineering wearing the title “CEO and Design Prophet.” He knows that feeling exactly. That's what Munro and his team are doing with an early edition of the Tesla Model 3 – the lower cost, so-called populist Tesla meant to draw in buyers who can't afford the upscale models but want to share in the futuristic vehiclular dreams of super visionary Elon Musk who is dedicated to putting transportation on a 22nd Century path.

Munro is the somewhat reticent founder and head of Munro & Associates, Inc., of Auburn Hills, Michigan. That is one of the “Automation Alley” communities home to many of the state's automotive support industries, and an expanding home of the industry's need for advanced technologies as it morphs beyond the internal combustion engine.

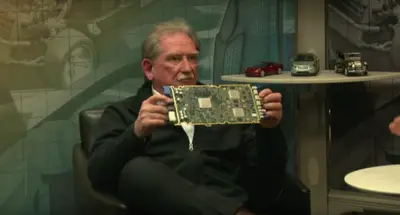

In an uncharacteristic gesture of visibility, Monro opened the doors of his benchmarking facility to members of Detroit's Automotive Press Association (APA) this week to show us the Tesla’s innards.

It wasn't easy getting a new Tesla Model 3 to pick apart. You don't just drive up to a Tesla dealer and put your cash on the line. There simply aren't any to be had. And, telling the company you want one of their vehicles to take apart like opening a can of tuna isn't likely to extricate one from inventory.

Instead, Munro was able to find one an early adopter who had put some $78,000 in cash up front to be first to own one. When Munro made the offer to buy it from him, the guy said yes. “He needed the money,” said Munro.

|

Walking through Munro's facility you might not realize you are looking at parts of a disembodied future car meant to change the driving and vehicle ownership habits of the more average American.

Tables were laden with pieces of the entire drawn-and-quartered Model 3. They included drivetrain components, interior appointments such as “vegan” (non-animal) luxury seat covers, electronic brains, automatic braking elements and mismatched front and rear brake calipers. They showed every aspect of the vehicle that Tesla predicts will sell in volume. (Apparently Michigan-based Meijer superstores feel the same way, as they are installing banks of Tesla-only electric vehicle charging stations outside some of their mega stores.)

Going beyond perceived packs of AA batteries might seem like a stretch. But Mark Ellis, one of the technical wizards who is part of the team, showed how the little battery rolls – each about the size of a prescription bottle – are welded together with an advanced super glue into bricks of 46. Those bricks then are aligned into four panels that lay flat on an undercarriage base, then completely covered. No matter where one is seated in the Model 3, he or she is sitting over a section of battery pack. It's eerily reminiscent of GM's experimental “Skateboard” architecture of the early 2000s that never made it to production.

Everything in the Tesla is glued together, said Ellis. And he can attest to its toughness compared with welding or bolting parts together. He had to use chisels and a lot of muscle to break components apart. That also means that the battery packs in the platform are there for good. There's no swapping out an individual dead battery within the array for a new one. But he said that each battery cell is so small that if one did fail it would have virtually no impact on the total electrical charge propelling it.

Munro's reverse engineering technique is meant to learn how the Tesla, and other subjects of their interest, are made. Each of the findings is assigned a specific number from 1 to 5 to indicate how poorly or well it is designed or made. The numbers are as objective as they can them, indicating quality of design, materials, assembly and, most important, their cost. “One” is low man on the totem pole, indicating that component has been poorly envisioned or executed. “Five,” however, shows leading-edge design, effective applications and, on some occasions, a good sense of humor. One set of circuitry boards had Batman and Robin designed into them with those names etched into the board in case it wasn't obvious.

Munro said the Tesla has both “1s” and “5s” with advanced technology rating a “6,” for its off-the-scale future thinking.

“Body in White” scored way low having unnecessarily excessive amounts of steel in odd places that added to weight, sharp edges from welding leakage and unnecessary complexity in assembly, including oddly mismatched attachment applications. Musk was recently quoted admitting they use too much robotics in the Model 3 assembly. Those factors seem to have added to Tesla's ongoing problems with fit and finish, about which many Tesla owners have complained. But, the electronic systems scored very high. Other numbers were all over the place.

The benchmarking of the Model 3 was not commissioned nor authorized by Tesla, so Munro has no need to provide a report of its ultimate findings to the company. But, Munro is free to sell the study in total or in parts to any OEM or other buyer interested in a copy. That includes Tesla. He calls it a payment of $78,000 for a million dollars-worth of research.

That brings up a couple of questions for the future. Since the Model 3 won't have a model year assigned to it, that could complicate things for the collector who might want to get a permanent historic license plate some years down the road. Those are based on the model year. (That's a 25-year-old model in Michigan.) And what happens if the battery packs finally do the dreaded deep six and the Tesla Model 3 becomes an expensive garage filler?

The general consensus: “You buy a new Tesla.”

© Martha Hindes, The Automotive Bureau