Toyota's Chief Scientist on Hydrogen vs. Lithium-Ion Batteries & Why We Need Both

Dr. Gil Pratt |

By Dr. Gill Pratt

Toyota’s Chief Scientist and Toyota Research Institute’s CEO,

Like the War of the Currents 150 years ago, today another war is being imagined - "War of the Elements" for energy storage and transport, between hydrogen, as used in fuel cells and engines, and lithium, as used in lithium-ion batteries

Instead of Thinking “Either/Or,” We Should be Thinking “Yes, And…”

Introduction and Summary

Nearly 150 years ago, Thomas Edison and George Westinghouse fought a battle for the supremacy of Direct Current (DC) vs. Alternating Current (AC) known as the War of the Currents.

Not only was the War of the Currents full of false accusations and intrigue, but the war’s short-term winner — AC — did not become the singular best solution in the long run. As vacuum tubes, then semiconductors, grew more common, DC took on an increasing role in the electrical chain from power generation to end-use. Today, both types of power — DC and AC — are used wherever each works best. AC is still used between power plants and buildings. But electronic equipment, including LED lighting, computers, and inverter-driven motors, increasingly convert AC to DC before use, while renewable power generation and storage increasingly converts from DC to AC.

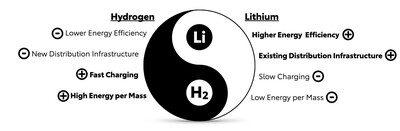

Like the War of the Currents 150 years ago, today another war is being imagined — a “War of the Elements” for energy storage and transport, between hydrogen, as used in fuel cells and engines, and lithium, as used in lithium-ion batteries.

With the benefits of 150 years of hindsight, what lesson can we apply from Edison and Westinghouse’s War of the Currents to today’s imagined War of the Elements?

It is that diversity is a better solution than monoculture.

In particular:

Lithium, when used in lithium-ion batteries, has high energy efficiency and uses existing charging infrastructure, but has low energy per mass and limited charging rate, making it impractical for large vehicles.

By contrast, Hydrogen, as used in hydrogen fuel cells and engines, has high energy per mass and a high charging rate, but lower energy efficiency and needs new charging infrastructure. In contrast to lithium-ion batteries, hydrogen particularly excels in large vehicles.

Each approach has its benefits and its drawbacks, and each is strong where the other is weak:

If we understand the complementary advantages of Lithium and Hydrogen, and the 150-year-old lessons from the War of the Currents, there is no need to pick a winner now, and no reason to impose a single winner when the likely best solution will be both, depending on circumstances.

In other words, there’s no need for a war at all.

Like my previous blog entries about the advantages of vehicle drivetrain diversity, the same universal lessons apply to energy storage and transport:

1. Diverse circumstances require diverse solutions,

2. What is best for the average is not best for all, and

3. The solution to uncertainty is diversity.

Instead of thinking “either/or” we should be thinking “yes, and…”

This is why Toyota is continuing to invest R&D resources in a wide range of possible energy storage and transport technologies. We believe that by doing so, instead of prematurely picking singular winners, the best possible diverse solutions, suited to a diverse range of applications, will emerge.

The Basics: Hydrogen

Hydrogen is the simplest and lightest element and is the most common element in the universe. Hydrogen is non-toxic, and when it reacts with oxygen releases significant amounts of energy and produces pure water:2 H2 + O2 ⇌ 2 H2O + 572 kJ of energy

The energy released from this reaction can be in the form of heat (which can run a steelmaking furnace or power an engine), or electricity from a fuel cell, shown below. >>>>>>>>FUEL CELL

If the fuel cell above looks a little like a battery, it’s no accident — both fuel cells and battery cells exploit similar physics to convert between chemical and electrical energy, except in fuel cells energy is stored externally in a tank, whereas in battery cells energy is stored inside the battery itself.

Since oxygen is plentiful in the air around us and also free, we need only store and transport hydrogen to store and transport energy.

Hydrogen has both advantages and drawbacks. Because of hydrogen’s low boiling point at normal pressure (20 degrees Kelvin which is super cold), it is harder to store and transport than room temperature liquid fuels like gasoline. Small molecules like hydrogen tend to leak from pipe fittings and can also penetrate the surface of inexpensive metals, making them brittle. Luckily, hydrogen is light and dissipates very rapidly and alternative materials are impervious to hydrogen. We’ll talk about hydrogen’s comparative efficiency shortly.

Lithium

Lithium sits directly underneath hydrogen on the periodic table and is the lightest solid element at room temperature and pressure.Lithium is around 500 times rarer on earth than hydrogen, but around 20 times more plentiful than other elements like nickel and cobalt that are also used in some lithium-ion batteries. Large reserves of lithium exist in South America, Australia, and other parts of the world.

Like hydrogen, lithium can be oxidized to release heat, but this is a disadvantage because when lithium is mixed with water, it produces hydrogen gas, which is flammable. This is why trying to put out a lithium-based battery fire with water makes things worse.

The real advantage of lithium is when it is used in battery cells. They work like fuel cells, but with internal instead of external storage of energy, as shown below:

Performance Comparisons

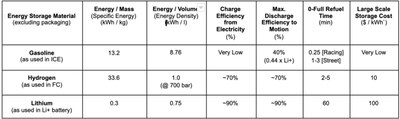

Performance: Energy per Mass (i.e. Specific Energy)

As seen in the table above, hydrogen stores very high amounts of chemical energy per mass — more than 100 times the electrical energy in the active parts of lithium-ion battery cells. This is why lithium-ion batteries are not practical for long-range aircraft — they simply weigh too much — and why hydrogen is a common rocket fuel. 2021 Toyota MiraiBecause of hydrogen’s very high energy per mass, the fuel tank of the Toyota Mirai carries only a tiny mass — 5 kg (11 lbs) — of hydrogen fuel, yet can power the Mirai over 400 miles between refuelings. In fact, a Mirai just set a world record of 845 miles on one load of fuel. Mirai’s Hydrogen-Powered Drive Train

Of course, to do a fair comparison, we must also take into account the additional mass beyond the active energy storage elements of each system.

For example, the 2021 Toyota Mirai FCEV weighs a few hundred pounds less than the similar size and range Tesla Model S long-range Battery Electric Vehicle (BEV). And a gasoline-powered Internal Combustion Engine (ICE) Camry weighs a few hundred pounds less than the Mirai.

Beyond hydrogen’s lower mass, the much larger mass of lithium-ion batteries needed by a long-range passenger car BEV consumes more natural resources, emits more carbon during manufacture, and is likely more costly to recycle than the equivalent equipment in an FCEV or Plug-In Hybrid Electric Vehicle (PHEV). And, because lithium-ion batteries are still improving and will be supply-limited for some time, placing many lithium-ion batteries into fewer long-range BEVs rather than many more smaller-battery FCEVs and PHEVs can result in less total carbon emissions reduction.

Larger Vehicles

Iberdrola Hydrogen Train + Airbus Hydrogen Plane

As vehicle size scales up, the 100X higher energy per mass of hydrogen gives hydrogen a much greater mass advantage in trucks, trains, ships, long-range aircraft (shown above), and spacecraft.

Recharge Time

A hydrogen tank can be recharged 10–100 times faster than lithium-ion batteries without the lifetime degradation suffered by rapidly charged lithium-ion batteries. This advantage becomes critical in larger vehicles like trucks, trains, planes, and ships, which must quickly replenish much larger reserves of energy.Because the energy content of chemical fuels is so high, the rate of energy transfer when a car’s fuel tanks are being filled with gasoline or hydrogen is 1–10 MegaWatts (MW). That’s 10–100 times the power of a 100kW level 3 DC BEV Supercharger. This is why it takes so much less time to fill up a car’s fuel tank (gasoline or hydrogen) than to fully recharge a BEV’s empty batteries.

Will this improve in the future?

Our research on solid-state batteries is aimed at just that. But even if the battery problem is solved, supplying several MW of electrical power to many individual recharging stalls will be very challenging. The electrical grid was not designed to deliver that much power to that many individual locations and will need substantial enhancement.

To understand why, consider this: The amount of energy stored in each gas station’s tanks is also extraordinarily high — enough to fully fill thousands of car’s fuel tanks, i.e several hundred MWh per station. There is no equivalent local storage in the electrical power grid. And a tanker truck unloads fuel into a station’s tanks at hundreds of gallons per minute — the equivalent of hundreds of MW of power — the level of power generated by a small nuclear reactor. Again, there is presently no equivalent in the electrical power grid.

To counteract the much slower recharge time of batteries compared to gasoline, Tesla pioneered the idea of overlapping time during supercharging, with passengers taking a break to eat or shop while their BEV is recharging. I have enjoyed doing this with my model X on long trips, but doing it often shortens the life of the battery and ties up a high capital resource — the supercharger.

Charging at Home

Prius Prime — Plug-in Hybrid Vehicle

In parts of the world with low population density (e.g. the US), and lots of at-home overnight off-street parking (e.g. US suburbs), light-duty electric vehicles will mostly be charged every evening at home.

A city parking garage

However, the vast majority of the population worldwide are city dwellers, and those with cars must often park them on the street or in dense public garages some distance from their homes without access to electrical power and associated personalized billing systems. It will take significant time and capital to provide such facilities for every vehicle parked overnight in cities. Until then, rapid charging/refueling will still be desirable.

Commercial and Heavy Vehicles

Commercial vehicles differ from light-duty vehicles because they travel much longer distances with much less time available for recharging, and are much larger (and energy-intensive) than passenger vehicles. Unlike a passenger car, which typically holds 15 gallons of fuel, a semi-truck holds hundreds of gallons. The required electrical power to recharge a truck in a short period of time is so high as to likely be impractical. Battery swap solutions are one approach, but long-range BEV batteries are heavy, and long-range batteries for truck BEVs are extremely heavy, making swapping very difficult. Other researchers have come to similar conclusions.Kenworth T680 Class 8 trucks powered by a Toyota fuel cell electric drivetrain

Which geographic, economic, and environmental circumstances will favor hydrogen vs. lithium for lightweight passenger vehicles is uncertain. But when vehicles get large, the scales tip substantially in the direction of hydrogen. This is why we are working so hard on our Port of Los Angeles 18 Wheeler program, illustrated above, and why there are also strong advantages for hydrogen in larger vehicles like trains (around 5000 gallons of diesel per locomotive fuel tank), long-range aircraft (a 787 has a fuel capacity on the order of a car filling station — over 30,000 gallons), and ships (that typically hold millions of gallons of highly polluting heavyweight “bunker” fuel). In the case of ships, it may be best to combine hydrogen with nitrogen to make ammonia.

Energy Efficiency

High round-trip energy efficiency is one of the strengths of lithium-ion batteries. Compared to chemically fueled engines, both lithium-ion batteries and hydrogen are more energy efficient. But generating hydrogen from electricity, compressing and storing it in a tank, and converting it back into electricity, loses around twice the amount of energy that is lost directly charging and discharging lithium-ion batteries.In some systems where energy loss must be minimized, lithium-ion batteries tend to be a better choice.

In other systems, including some renewable energy ones, total cost is more important than energy efficiency. For example, the solar cells chosen for large commercial photovoltaic power stations are only about half as energy-efficient as the most energy-efficient solar cells available.

A solar farm

Because the cost of the land underneath the solar cells is low, using larger, less energy-efficient — but also less costly — solar cells above and more land below can result in lower net cost for each kWh of energy produced.

In a similar way, because the cost of renewable energy has dropped so much, the lower energy efficiency of hydrogen may be a less important factor. The energy shortages of the past taught us to value energy efficiency. But today energy supplies are plentiful while reducing greenhouse gas emissions and cost are more important. Energy efficiency isn’t everything.

How about Hydrogen ICEs?

This hydrogen engine Corolla participated in its first race on May 21, 2021 at the Fuji SUPER TEC 24 Hours Race at Fuji Speedway.

Recently, Toyota demonstrated a hydrogen internal combustion engine race car, shown above.

A hydrogen engine in action

The wonderful YouTube Channel, Engineering Explained, has several videos on hydrogen engines, with well-reasoned critiques. Because ICEs have lower efficiency than fuel cells, unless pressures are raised fuel tanks need to be larger than in comparable FCEVs. But hydrogen ICE drivetrains may have higher durability, lower environmental and financial manufacturing costs, and lower total cost of ownership than hydrogen fuel cell drivetrains, particularly at larger sizes.

There are also significant advantages to hydrogen ICEs and PHEVs because they can use the existing ICE supply chain. We have a social responsibility to consider the economic and human cost of labor displacement as well.

Costs and Benefits of Storage

As the amount of energy that needs to be stored increases, fuel cell systems become less costly than batteries, because the increased energy storage only requires a bigger fuel tank, not a bigger fuel cell. With batteries, the only way to scale up is to add more cells. In fact at large scales (shown below) the cost of storing energy in hydrogen, even as a liquid at cryogenic temperatures is 1/10 the cost of storing the same energy in lithium-ion batteries.Japan’s largest liquid hydrogen storage tanks

Energy storage will become more important as intermittent renewable energy sources like solar and wind, make up a larger fraction of the world’s energy supply. As these sources of power grow, there will be an increasing need for long-term energy storage to level out day/night and seasonal changes in power production and demand.

At such large energy and long time scales, lithium-ion batteries are prohibitively expensive, both financially and environmentally. While large-scale energy storage schemes like pumped hydro are also possible, their costs, both financial and environmental, depend strongly on location. Similarly, while producing zero carbon liquid fuels for certain applications (like ammonia for ships, kerosene for aircraft, and ethanol for Units In Operation (older) cars) will be needed, if hydrogen becomes a major means of storing energy for leveling, it will also become less costly and more available for other uses, like FCEVs and Hydrogen ICE vehicles.

Transport

The creation of electrical power grids in the 20th century was a tremendously important milestone in civilization. But so too were pipelines, both in ancient times for water and more recently for other key liquids, especially fuels.It is easier to build an overnight lightweight passenger BEV recharging station than a hydrogen FCEV refueling station because the electrical grid is already present and the power levels required for overnight charging are modest. But as rapid charging during long-distance trips or recharging of larger vehicles is considered, the level of power required becomes impractical, and using hydrogen becomes more attractive. Larger vehicles also tend to travel less diverse and diffuse routes, which increases the practicality of hydrogen refueling.

Still, transporting hydrogen long distances over pipelines is presently expensive, both because of hydrogen embrittlement and leakage, though some companies are working on innovative shipping methods.

Production

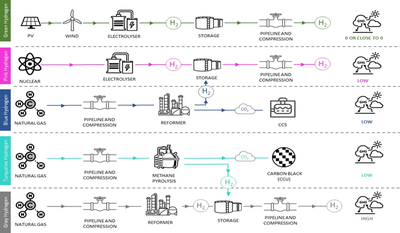

Like charging a lithium-ion battery, hydrogen can be produced from water through the process of electrolysis (a fuel cell running backward) but hydrogen can also be produced in other ways, as shown below:

Hydrogen production options

The most common way hydrogen is produced today is via steam reformation of natural gas. This creation of “grey” hydrogen, unfortunately, creates as much CO2 as simply burning the natural gas. But the same technology used to drill for oil and gas can be used to sequester the CO2 deep underground, creating blue hydrogen. In fact, CO2 is already used in wells to push oil and gas to the surface.

As seen above, much lower carbon methods of generating hydrogen are also being developed, with huge investments from industry, including green hydrogen from renewable power electrolysis of water, pink hydrogen from electrolysis driven by nuclear power, and turquoise hydrogen from high-temperature pyrolysis of methane.

Some natural gas in the production and distribution process presently leaks into the atmosphere, and methane, the largest component of natural gas, is a very potent greenhouse gas (though shorter-lived than CO2). However, such “fugitive emissions” do not make blue and turquoise hydrogen inevitably high carbon. Leaks can be corrected and prevented, especially if hydrogen production is at hubs located near natural gas production facilities.

Furthermore, there is significant experience in producing hydrogen. The US presently produces 10 million metric tons of hydrogen per year — mostly for the production of fuels and fertilizers. This is equivalent to 2 billion fill-ups of the Toyota Mirai’s 5 kg fuel tank.

Conclusion

The question of hydrogen vs. lithium-ion batteries is one of many examples of attempted technological prediction. It is comforting to think that we can predict what will be best in the future and remove uncertainty from such important choices.However, as the War of the Currents demonstrated, we cannot foresee which particular technical solutions will be best in the future, or whether only one will be best. So it is important we understand the lessons of that long-ago technological war: that the solution to uncertainty is diversity, and, because the world is not uniform, diverse circumstances require diverse solutions — what is best for the average is not best for all.

We know the problem: climate change. And we know the enemy: greenhouse gases. And we know how to measure our progress: the reduction of net emissions over time.

Besides these certainties, no matter how strident and well-meaning some may seem today in advocating particular answers, we are all in truth uncertain what solutions will be best in the future.

Toyota generally believes that companies should be held to strict science-based limits on the net production of greenhouse gases. Beyond that, we do not think that policymakers should pick winning technologies and impose predetermined solutions.

Toyota believes in the inherent advantages of diversity. Climate change is not failing to be addressed because R&D resources are being spread too thin on too many possible solutions. Instead of trying to predict winners, we should be constantly experimenting in search of better answers.

So let’s tighten the screws on the required reductions in greenhouse gases and let the brilliance of human creativity figure out how to get it done. Instead of criticizing companies for trying different approaches, let’s celebrate them for being willing to invest their resources in a range of possible solutions so that the best answers will emerge.

And let’s embrace diverse solutions as a general principle. While it’s tempting to look for simple solutions, climate change is such a varied and dynamic problem that we need to explore multiple approaches.

Significant progress is being made both in the cost and performance of lithium-ion batteries and also in the cost and elimination of greenhouse gas emissions in the production of hydrogen.

I am optimistic that if we encourage companies to develop many innovative ways to reduce greenhouse gases, we will succeed.

No war required.

The above argument was made by Dr. Gill Pratt, Toyota’s Chief Scientist and Toyota Research Institute’s CEO, in his latest TRI Medium blog.